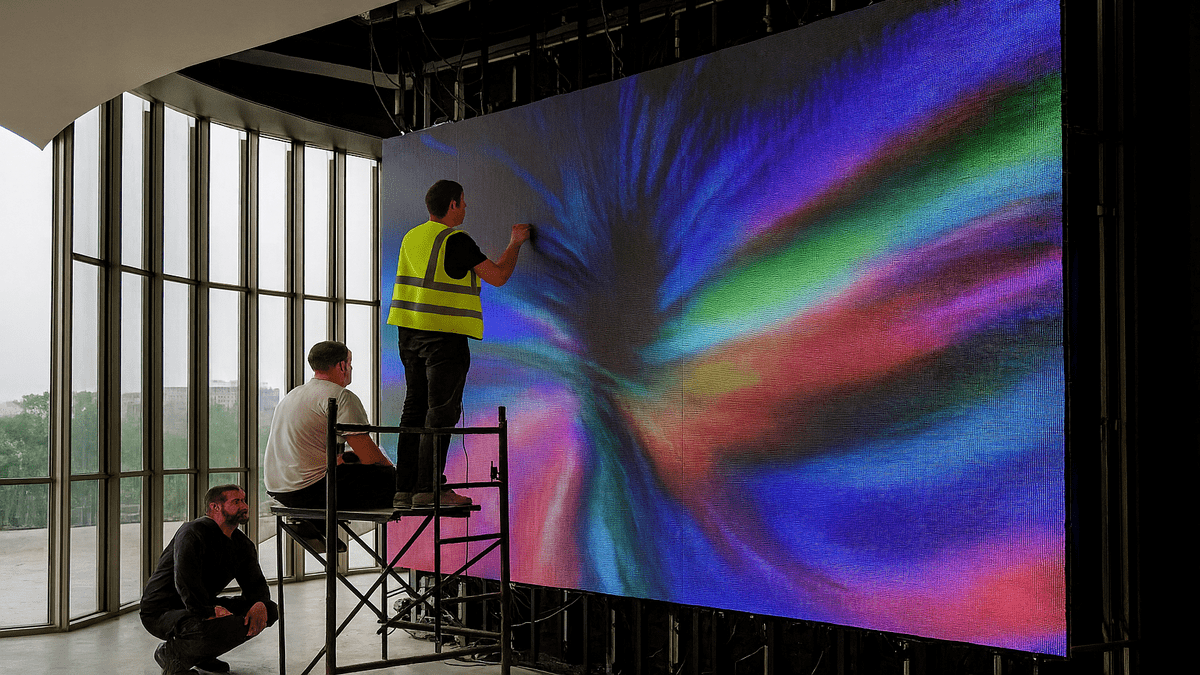

Installing LED video walls is simple in standard rooms, but many modern buildings include glass partitions, curved surfaces, tight corners, or low ceilings. These conditions create serious Installation Challenges of LED Video Walls in Non-Standard Spaces that demand precise planning and advanced engineering. This article explains the most common problems and the professional methods used to overcome them.

Understanding Non-Standard Installation Environments

What Qualifies as a Non-Standard Space?

A non-standard space is any installation environment that lacks the traditional load-bearing wall, depth clearance, or structural uniformity needed for direct mounting. Examples include:

-

Glass partitions and full-glass storefronts

-

Curved or angled architectural features

-

Irregular shapes and tight corners

-

Spaces with minimal ceiling height

-

Floating or suspended structures

-

High-humidity or outdoor-exposed interiors

Each of these scenarios presents unique Installation Challenges of LED Video Walls in Non-Standard Spaces, especially regarding weight distribution, vibration, safety codes, and access for service.

Structural and Engineering Challenges

Installing on Glass Surfaces

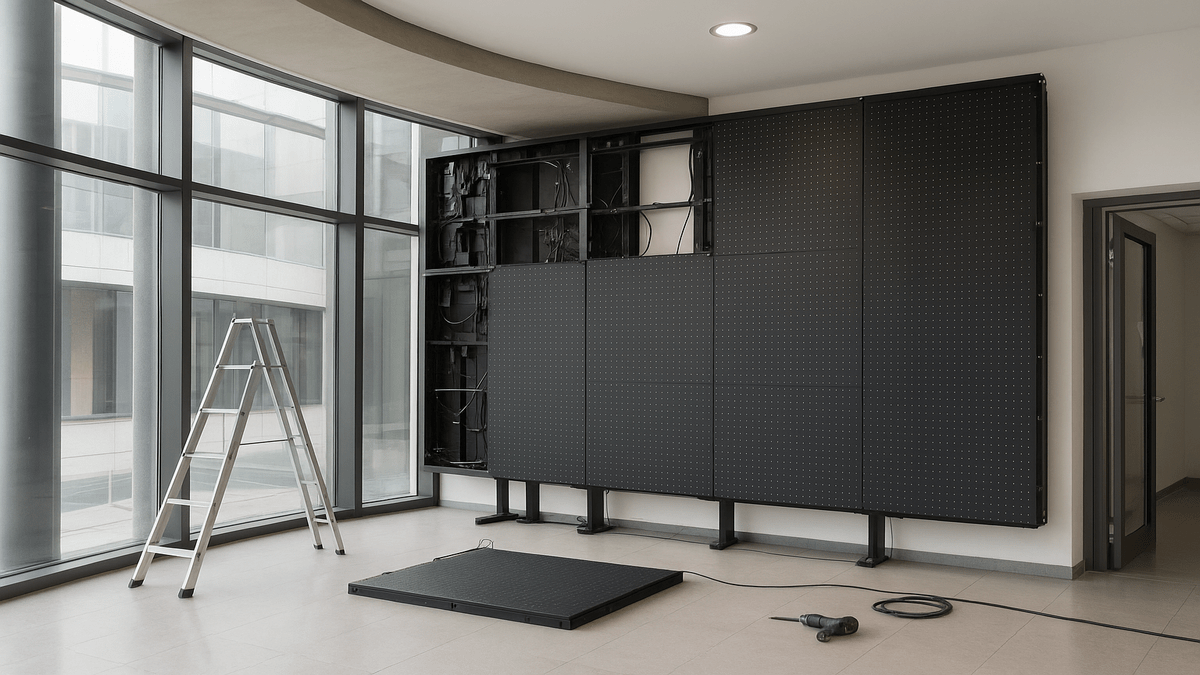

Glass surfaces do not provide the rigidity or load capacity required to support LED cabinets. Installers must use auxiliary frames, freestanding structures, or floor-mounted supports. Engineering analysis becomes essential to determine whether nearby architectural elements can handle the additional load. In some retail environments—such as shops that also use Digital Screens for Hairdressers and Beauty Salons—installers often face situations involving decorative glass dividers that require highly customized mounting solutions.

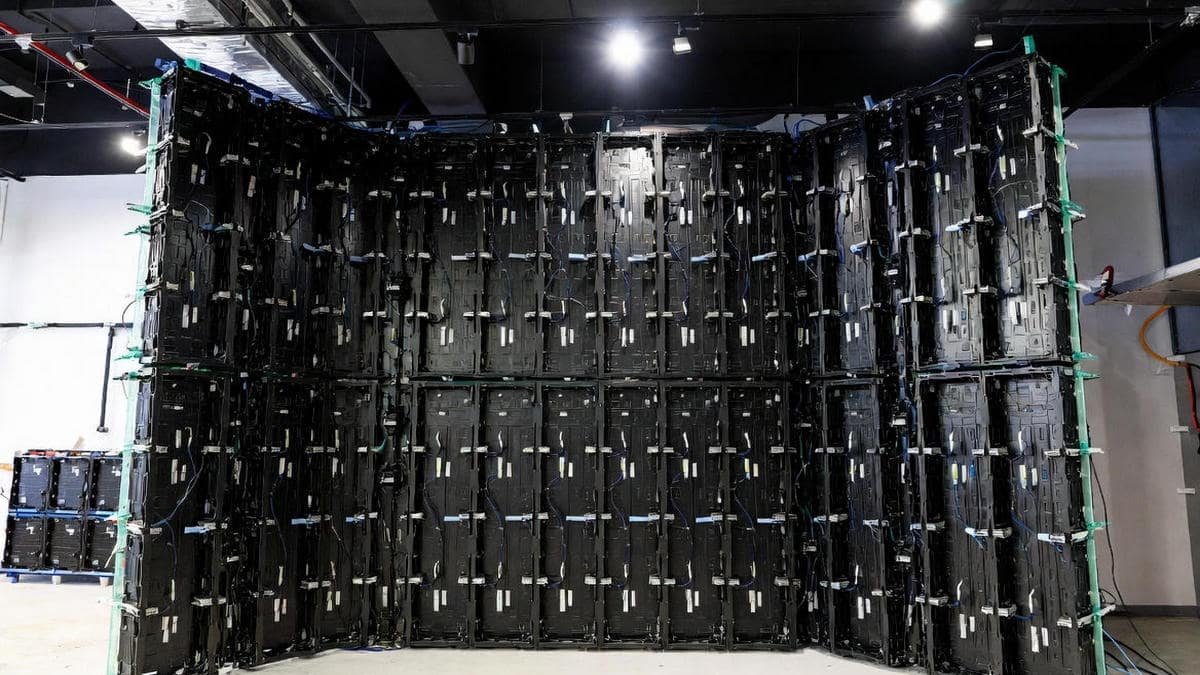

Irregular and Curved Walls

When dealing with curved or unconventional surfaces, custom brackets and adjustable frames must be designed. Even minor curvature can cause cabinet misalignment, resulting in visible seams or pixel distortion. Addressing such Installation Challenges of LED Video Walls in Non-Standard Spaces requires laser measurements, 3D modeling, and often CNC-machined components. The slightest deviation can compromise structural integrity or aesthetics.

Low Ceiling Constraints

Low ceilings create difficulties for both front-service and rear-service panels. Installers must evaluate maintenance access routes and airflow limitations. In some indoor venues, ceiling height may also restrict the angle at which the video wall can be viewed comfortably. This leads to the need for recessed frames or ultra-slim mounting systems.

Environmental and Thermal Considerations

Heat Management in Confined Spaces

LED panels produce heat, and non-standard installations often restrict airflow. Without proper thermal management, the system’s lifespan can shrink dramatically. Installers must factor in ventilation paths, forced-air systems, and heat-resistant materials. Many integrators rely on Digital Signage Cooling techniques—including silent fan systems or passive ventilation channels—to keep temperatures below manufacturer thresholds.

Humidity and Outdoor–Indoor Hybrids

Certain installations occur in atriums, semi-open malls, or indoor areas exposed to high humidity. Protection against moisture, dust, and oxidation becomes critical. Even if the LED display is rated for indoor use, the surrounding environment might require outdoor-grade power supplies or sealed cabinets. This is another example of Installation Challenges of LED Video Walls in Non-Standard Spaces that installers often overlook.

Electrical and Cabling Challenges

Limited Access for Power and Data Routes

In traditional settings, cables can run behind a wall or above a ceiling. In non-standard environments—especially glass or suspended installations—there may be no hidden pathways. Installers must design creative routing options through floor trenches, decorative columns, or custom conduit enclosures.

Integration with Existing Infrastructure

Some projects require adding video walls to older structures where electrical capacity is limited. In these scenarios, integrators sometimes turn to Retrofit Signage Solutions, which allow the system to be installed without extensive demolition or rewiring.

Safety and Compliance Requirements

Electrical compliance regulations vary around the world. Load distribution, grounding, fire safety spacing, and emergency shutoff requirements are all part of the Installation Challenges of LED Video Walls in Non-Standard Spaces, especially for public venues, airports, and transportation hubs.

Mounting and Mechanical Constraints

Choosing the Right Mounting System

Mounting systems must support weight, resist vibration, and align cabinets precisely. Non-standard environments require:

-

Lightweight aluminum frames

-

Adjustable multi-axis brackets

-

Reinforced freestanding towers

-

Ceiling-suspended rigs

-

Overhead truss systems

Precision Alignment in Difficult Conditions

LED cabinets must align perfectly to avoid visual distortion. Achieving micro-adjustments becomes far more difficult in curved, angled, or floating installations. Installers must plan for accessibility, expansion, and serviceability long before construction begins.

Specialized Scenarios and Advanced Challenges

High-Traffic Public Areas

Airports, malls, and city centers often require elevated or suspended LED video walls. These environments demand vibration-resistant mounts, fail-safe secondary tethering, and compliance with strict safety codes. The complexity of these Installation Challenges of LED Video Walls in Non-Standard Spaces often requires collaboration with structural engineers.

Vehicle-Based or Mobile Applications

In mobile environments—like ad trucks or taxi roof displays—weight, power stability, and vibration are critical. For example, Taxitop LED Displays in Australia must withstand heat, wind pressure, and vehicle movement while maintaining stable display performance.

Architectural Integration with Design Aesthetics

Designers often want video walls built into custom furniture, partitions, or stage elements. These cases require both artistic and engineering coordination. Hidden supports, seamless cable routing, and integrated ventilation must be incorporated without compromising the creative concept.

Best Practices for Overcoming Installation Challenges

1. Detailed Site Survey and Structural Analysis

Every non-standard installation begins with accurate measurements and a load-bearing study. Laser scanning tools and digital modeling help identify problem areas early.

2. Collaboration with Architects and Engineers

Architects understand the building’s limitations, while engineers ensure compliance and structural safety. Working closely with both reduces major risks.

3. Custom Mounting and Fabrication

Off-the-shelf mounts rarely work for irregular spaces. Fabricators can create brackets and frames that conform to curved or angled surfaces.

4. Planning for Serviceability

Maintenance access must be considered at the design stage. Front-service panels, removable frames, or hinged structures may be necessary.

5. Thermal Management

Heat modeling and airflow analysis prevent overheating—one of the most common Installation Challenges of LED Video Walls in Non-Standard Spaces.

6. Testing Before Final Deployment

Mockups and off-site assembly tests allow installers to verify alignment, cabling, and thermal behavior before shipping equipment to the final location.

Conclusion

Non-standard spaces introduce complex Installation Challenges of LED Video Walls in Non-Standard Spaces, including structural, thermal, electrical, and mechanical constraints. By combining engineering expertise, customized mounting solutions, and detailed planning, installers can ensure safe, reliable, and visually stunning results—even in the most challenging architectural environments.