In recent years, the adoption of transparent LED technology for retail storefronts, architectural façades, and corporate lobbies has surged. For any architect, AV integrator, or facilities manager evaluating systems, a clear understanding of Transparent LED Screens Installation Methods is essential. The right installation strategy not only affects visual performance but also structural safety, maintenance overhead, and long‑term durability. With so many options on the market — varying from mesh curtains to glass‑integrated panels each project demands a tailored approach that fits site constraints, aesthetic goals, and budget limitations. This comprehensive review will guide you through critical factors, real‑world scenarios, and best practices to ensure your transparent LED installation succeeds.

As more organizations explore ways to integrate luminous displays without obstructing natural light or impacting building aesthetics, many teams attempt to make a transparent LED display by themselves or under oversight. That ambition demands careful planning structural load calculations, glass strength ratings, and power supply location are among the early considerations. Rushing into installation without these preparations often leads to costly retrofits or even display failure. Clarifying in advance how the display will be anchored, serviced, and powered can save time and money while reducing the risk of long‑term damage.

Common Transparent LED Screens Installation Methods Overview

When evaluating Transparent LED Screens Installation Methods, it helps to break down the most widely adopted approaches: hanging‑frame mounting, structural‑glass integration, floor‑standing modules, and mesh curtain‑style panels. Each technique has strengths and trade‑offs in terms of transparency, load distribution, ease of maintenance, and upfront cost. Understanding these pros and cons is the foundation for selecting the most suitable method for your site. Moreover, choosing the right method early influences glass selection, glass treatment (e.g. tempered or laminated), and even building permits or fire codes.

Hanging‑Frame Mounting

One of the most straightforward approaches involves a metal or aluminum frame installed directly to the surrounding structure typically above a storefront window or behind a transparent storefront wall. LED panels are then secured into that frame, suspending the entire display slightly inside or outside the glass plane. This method provides easy access for maintenance and repair, and minimizes stress on existing glass. Additionally, hanging‑frame mounting simplifies alignment because the frame defines the panel geometry, ensuring flatness and uniform spacing. However, it requires precise calibration during installation to ensure the display stays level and flush; improper leveling can cause light leakage at edges or visible seams. It also adds a visible frame edge, which may not suit ultra‑minimalist architectural designs.

Structural Glass Integration

For a sleek, seamless aesthetic, structural‑glass integration embeds LED modules directly between or behind double‑glazed glass panels. The glass is engineered to carry both the load of the LED modules and environmental stresses like wind or vibration. This method produces minimal visual distraction and preserves transparency when the display is off, offering a near‑invisible footprint. The trade‑off is that glass strength and mounting hardware must be carefully specified, which can significantly increase project cost and complexity.

Integration often requires custom laminated glass, reinforced mullions, and precise waterproofing to prevent condensation or ingress. Once sealed, however, these installations offer excellent durability and minimal maintenance, making them ideal for flagship retail spaces or premium office lobbies that demand both clarity and a clean look.

Floor‑Standing Module Assemblies

In scenarios where overhead mounting is impractical or building codes restrict wall attachments, floor‑standing modules can be used to anchor transparent LED panels from the ground up. Designers often choose this when renovating older buildings or retrofitting open‑plan interiors without modifying structural walls. If you want to make a transparent LED display that can be relocated or removed without altering walls or glass, this modular approach is practical. Anchored to a weighted base or a custom pedestal, these modules allow for flexible placement, such as in front of glass façades or inside glass‑walled rooms. They are especially useful for pop‑up events, temporary retail spaces, or flexible exhibition setups. That said, care must be taken to prevent tipping and to distribute weight evenly, especially in seismic zones or on uneven flooring; engineers may need to perform stability calculations or add anchoring plates for safety.

Mesh Curtain Style Panels

Another popular method involves attaching LED modules onto a light, flexible mesh that hangs like a curtain in front of or behind glass. This curtain‑style installation is especially beneficial when maximizing transparency and minimizing weight are priorities, such as in high end retail showrooms or atria. Because the mesh is light, structural loads are minimal, and installers can avoid complex framing or drilling into concrete. That significantly reduces installation time and minimizes structural intrusion. However, curtains must be carefully tensioned to prevent sagging or visible deformation, which could cause pixel alignment issues or premature wear. Additionally, the mesh may sway slightly if exposed to airflow for example, from air conditioning or open doors potentially causing motion blur or light variation unless adequately secured and tensioned.

Environmental and Load Planning Considerations

One critical dimension in Transparent LED Screens Installation Methods is environmental stress: exposure to direct sunlight, temperature swings, humidity, and even airborne pollutants can all degrade LED performance over time. For example, installing panels where interior glass faces south in a desert‑like climate might push components beyond their thermal tolerance a scenario akin to a LED screen from Extreme Heat test environment. Engineers must specify materials rated for UV resistance, robust sealed seams, and temperature tolerant components. It is also important to consider load distribution: glass façades often were not designed to carry extra weight, so adding LED modules can exceed structural limits. Prior structural analysis and consultation with a certified structural engineer are vital; neglecting these factors may shorten lifespan or lead to component failure, cracked glass, or safety hazards.

Ventilation, Cooling, and Heat Management

Proper cooling and airflow behind or within the LED modules are vital for long‑term reliability. Without adequate ventilation, heat buildup can accelerate component degradation, cause color shifting, or trigger thermal shutdown. During install and maintenance, technicians should consider forced‑air cooling, perforated backing plates, or heat sinks guided by guidelines to Optimize Digital Signage Cooling for Maximum Performance.

Proper cooling and airflow behind or within the LED modules are vital for long‑term reliability. Without adequate ventilation, heat buildup can accelerate component degradation, cause color shifting, or trigger thermal shutdown. During install and maintenance, technicians should consider forced‑air cooling, perforated backing plates, or heat sinks guided by guidelines to Optimize Digital Signage Cooling for Maximum Performance.

Transparent installations often sit close to large glass surfaces where heat can accumulate, so heat extraction must be designed to avoid hot spots. Regular airflow audits and periodic cleaning of vents will further extend the usable life of the installation. Additionally, moisture control and condensation prevention are critical, especially in humid climates or spaces with air‑conditioning cycles; sealed channels and desiccant packs may be needed to prevent fogging or water damage.

Adapting to Non Standard Architecture and Spaces

Not all buildings offer clean rectangular façades or standard wall‑to‑glass proportions. Some modern retail or corporate environments demand adaptable solutions to fit curved glass, sloping atria, or narrow window bays. In these cases, you may explore Transparent LED Screens Installation Methods tailored for irregular geometry. This flexibility finds analogy in LED Video Walls in Non Standard Spaces where integrators craft bespoke support structures, custom brackets, or segmented modules so the display fits flush even on angled glass or curved surfaces.

Such customization ensures both aesthetic harmony and technical stability. Moreover, for heritage buildings or spaces with restricted drilling permissions, modular and reversible installations preserve the integrity of surfaces while still delivering high‑impact visuals. Project managers must coordinate early with structural engineers, preservation authorities, and glass suppliers to ensure compatibility.

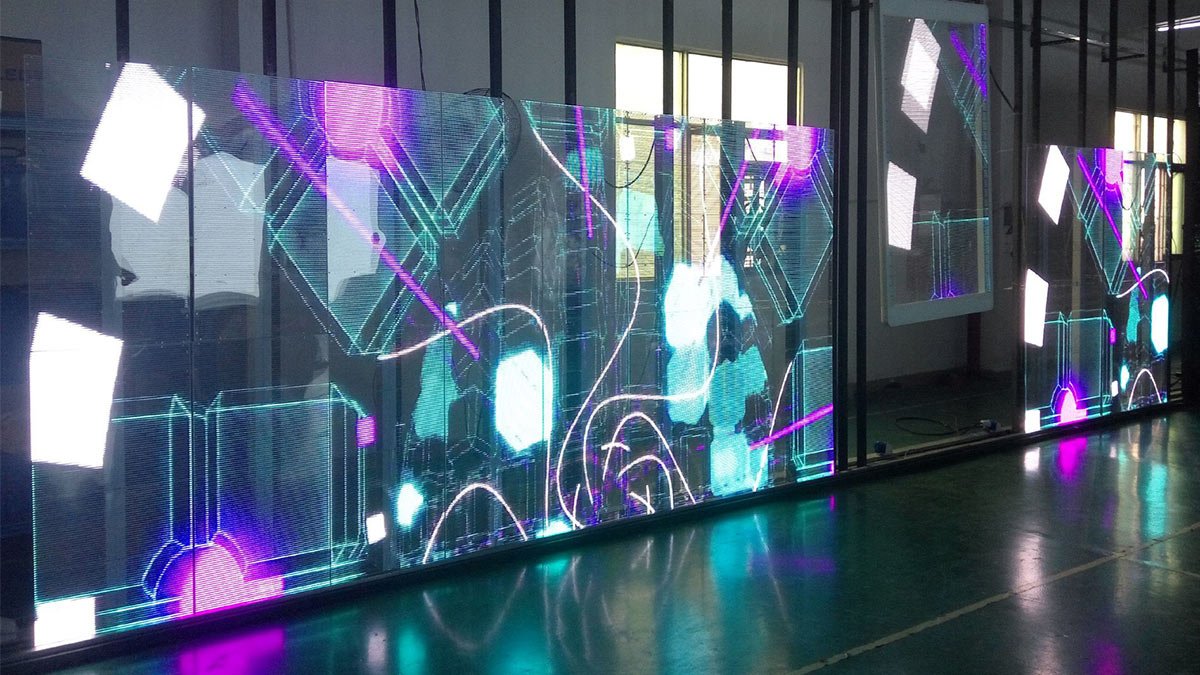

Creative Use Cases: Integration Beyond Static Displays

Transparent LED panels are no longer confined to retail storefronts or signage modern studios and event venues leverage them for immersive content delivery. For high‑end production houses, Transparent LED Screens Installation Methods must consider not only mounting but also content synchronization, brightness calibration, and environmental control.

Such installations are particularly well‑suited for Virtual Production with LED Walls, where background scenery blends with real actors and transparent panels help maintain natural lighting. In such a context, installers must account for pixel pitch, refresh rate, and color calibration, while ensuring structural alignment and stability under studio lighting conditions. This versatility makes transparent LED technology appealing for broadcast, film, or architectural visualization firms that need dynamic, light‑permeable displays without blocking surroundings.

Common Pitfalls and Mistakes to Avoid

Many failed installs of transparent LED systems stem from underestimating structural load, neglecting weatherproofing, or skipping proper alignment checks. Some teams try to make a transparent LED display too quickly ignoring site measurement, weight distribution, or glass integrity and end up with skewed panels or cracked glass, which can be dangerous and expensive to repair. Others bypass recommended cabling standards or choose subpar modules, which leads to uneven brightness, dead zones, or premature failures.

Many failed installs of transparent LED systems stem from underestimating structural load, neglecting weatherproofing, or skipping proper alignment checks. Some teams try to make a transparent LED display too quickly ignoring site measurement, weight distribution, or glass integrity and end up with skewed panels or cracked glass, which can be dangerous and expensive to repair. Others bypass recommended cabling standards or choose subpar modules, which leads to uneven brightness, dead zones, or premature failures.

Overlooking maintenance access is another common mistake: panels installed flush behind glass may look sleek but can be extremely difficult to service if connectors or power supplies are inaccessible. Documenting installation steps, verifying component certifications, and scheduling post‑install inspections are essential to avoid these errors. It’s also wise to plan for potential future upgrades designing modular frames or accessible cable channels from the start saves time and money down the road.

Safety, Compliance, and Quality Assurance

Any installation must meet local building codes, fire regulations, and electrical safety standards. When applying Transparent LED Screens Installation Methods in commercial spaces, stakeholders should obtain structural calculations, fire‑resistant sealants, and certified wiring. Maintenance access must be considered at design time technicians will require safe platforms, proper grounding, and cable management to service the panels. In glass‑integrated or façade installations, laminated safety glass with appropriate fire‑rated sealants may be mandatory.

If ventilation ducts or conduits are added, their design should not impair fire‑safe pathways or violate ventilation standards. Ensuring compliance from the outset reduces liability, lowers insurance costs, and improves the longevity and reliability of the installation. Including a clear maintenance schedule with periodic inspections helps detect potential issues before they lead to failures or safety hazards.

Conclusion

In summary, successful Transparent LED Screens Installation Methods depend on careful planning, appropriate method selection, and ongoing maintenance. Whether you choose a hanging frame, structural‑glass integration, floor‑standing setup, or mesh curtain system, every project benefits from understanding load requirements, environmental factors, and cooling needs. If you intend to make a transparent LED display that balances aesthetics with durability, adhering to best practices outlined here will serve you well. With thoughtful execution and attention to detail, you can achieve a high‑impact transparent LED installation that performs reliably for years.